| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : JINRUI

Model Number : LSY

Certification : ISO/CE

Place of Origin : HENAN,CHINA

MOQ : 1 set

Price : USD 680-USD 9800/SET

Payment Terms : L/C, T/T, Western Union

Supply Ability : 5SET PER 10 DAYS

Delivery Time : 10-12 WORK DAYS

Packaging Details : seaworthy wooden box packing or packed by steel structure

Application : Mining,Sand,Powder

Warranty : 12 month

Voltage : 380/410/460/480v

Screw blade mateialls : Stainless steel

Angle : horizontal

Product name : Tubular screw conveyor

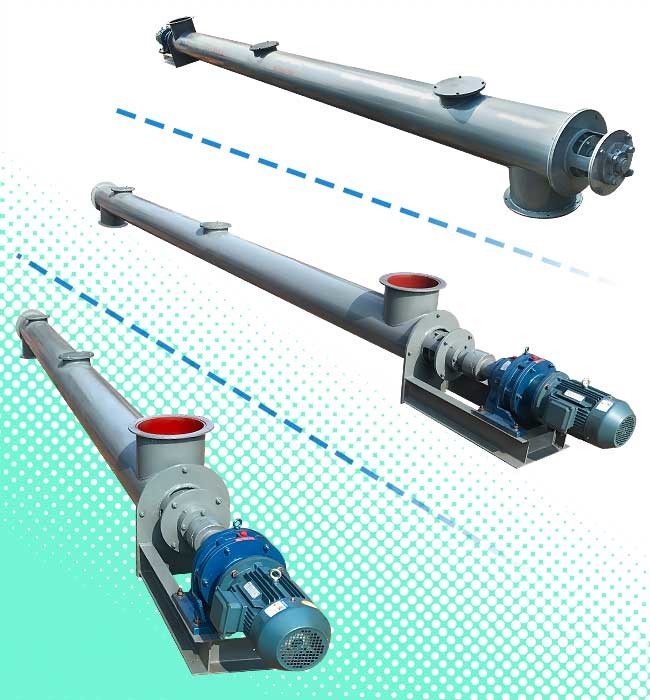

LSY 219mm Diameter Seamless Pipe Tubular Screw Conveyor With Hanger Bearing

LSY series screw conveyor is a new type of conveying equipment that uses rotating spiral blades to continuously push materials in a closed circular section shell. It can convey non-sticky dry powder materials and small particle materials, such as cement, powder Coal ash, lime, etc.

Characteristics are below:

Simple and compact structure, small cross-sectional area, good airtightness, convenient operation, easy maintenance, convenient for closed transportation, small cross-sectional area, light weight, good airtight performance, high conveying efficiency, flexible process layout, convenient assembly, disassembly, and movement. Safe operation. It is suitable for conveying various powdery, granular and small bulk materials, such as clay powder, coal powder, cement, sand, grain, small coal, pebbles and cast iron cutting, etc. Not suitable for conveying materials with high viscosity, agglomeration and deterioration.

The screw conveyor uses the rotating screw to move the conveyed material along the fixed casing to carry out the conveying work. The head and tail bearings are moved to the outside of the casing. The hanging bearing adopts a sliding bearing and is equipped with a dust-proof sealing device. The bearing bush is generally used Powder metallurgy, the conveying cement adopts felt bearing bushes, and the suspension shaft and the screw shaft are connected by sliding blocks.

1. The center line of the trough and the screw shaft should maintain good coaxiality.

2. The joints between the sections of the trough should be tight and there should be no misalignment. Gaskets can be added between the sections and between the top cover and the trough to ensure the sealing of the trough. At the same time, the length error of the trough can also be adjusted.

3. The gap between the inner wall of the trough and the spiral body should be equal.

4. The drive shaft and the screw shaft should maintain good coaxiality. When adjusting, the height of the drive device can be adjusted with the help of a spacer.

5. After the spiral body is installed, a static balance test should be carried out.

6. The intermediate suspension bearing should reliably and properly support the connecting shaft to avoid radial deformation of the screw shaft. The installation can be achieved by adjusting the gasket between the bearing bushes.

7. After the whole machine is installed, check whether there is any sundries in the machine and whether all lubricating places are filled with enough lubricating oil.

8. During the no-load test run, the bearing should not leak oil, and the bearing temperature rise should not exceed 20°C. During the load test, the bearing temperature rise shall not exceed 30°C.

| Model number | LSY140 | LSY160 | LSY200 | LSY250 | LSY300 | LSY400 | ||

| Screw diameter(mm) | 140 | 163 | 187 | 238 | 290 | 365 | ||

| Rotating speed(r/min) | 300 | 300 | 260 | 200 | 175/300 | 175 | ||

| Outer diameter(mm) | 168 | 194 | 219 | 273 | 325 | 402 | ||

| Max length(m) | 11 | 12 | 13 | 16 | 18 | 18 | ||

| Incline degree(α°) | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~55° | 0°~55° | ||

| Conveying capacity(t/h) | 9月17日 | 30-20 | 50-32 | 70-53 | 82-60/120-85 | 140-110 | ||

| Motor | Model | L≤-7 | Y132S-4 | Y132S-4 | Y132M-4 | Y160L-6 | Y180M-4 | Y180M-4 |

| Power(kw) | 5.5 | 5.5 | 7.5 | 11 | 18.5 | 18.5 | ||

| Model | L>7 | Y132S-4 | Y132M-4 | Y160M-4 | Y180L-6 | Y180L-4 | Y180L-4 | |

| Power(kw) | 5.5 | 7.5 | 11 | 15 | 22 | 22 | ||

|

|

Stainless Steel Pipe Horizontal Screw Conveyor Auger Screw Feeder Images |