| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : JINRUI

Model Number : YJD-A

Certification : ISO

Place of Origin : Henan

MOQ : 1 PC

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 10 sets per week

Delivery Time : 3-5 work days

Packaging Details : according to the model packed into woodcase

Material : Carbon Steel,cast iron,ss304

Product name : Feeding Small Granular Materials 16L/R 300mm Diamater Impeller Feeder

Application : Small Granular Materials

Power type : BWD motor reducer

Warranty : 12 months

Condition : New

Capacity(t/h) : 16L/R

The impeller feeders are the main machines for discharging dust powder, air supply and other equipment feeding, which is suitable for granular materials and powder materials.Impeller feeders are widely used in chemical industry,environmental protection, grain, metallurgy and other industrial sectors.

a. The impeller feeders are low noise and smooth operation ;

b. The impeller feeders have air locking function and high processing precision. Impeller feeders can be used as the quantitative feeder of powder in crushing and classification systems, and as the unloader of separation, dust collection and other systems.

c. Because the bearing and the tooth shell are at a distance from the box, the high temperature lubrication has been greatly improved.

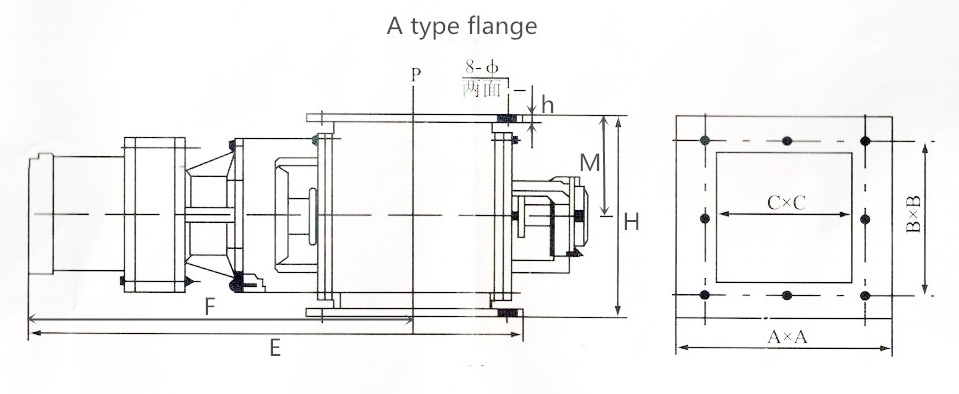

d. Cast iron, cast steel, stainless steel, can be used, and the flange can be square or circular , other structural forms to meet the different needs of users.

The impeller feeder is equipped with a cycloid reducer, which is rigidly and directly connected to the main shaft through the reducer shaft, so as to drive the main shaft and impeller rotation. The impeller is equipped with a number of impeller blade, which are equipped with rubber sealing pieces, pressed by a pressure plate, and the sealing pieces are close to the inner wall of the shell. When the motor rotates, the main shaft and impeller rotate at the same time, and the material enters the impeller slot from the upper bin through the inlet, and the rotating impeller takes the material to the outlet and feeds it out.

YJD A Model Rigid Impeller Feeder Parameter

| Model | YJD2 | YJD4 | YJD6 | YJD8 | YJD10 | YJD12 | YJD14 | YJD16 | YJD18 | YJD20 | |

| Name | |||||||||||

| Capacity(L/R) | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | |

| r/min | 25-40 | ||||||||||

| Temp(℃) | T ≤80℃ when temp is more than 80 ℃,need to custom made. | ||||||||||

| Product | Powder or fine particles | ||||||||||

| Motor | KW | 0.55 | 0.75 | 1.1 | 1.5 | ||||||

| r/min | 1300 | 1300 | 1400 | 1430 | |||||||

| Model | A | B | C | E | F | M | H | h | φ |

| YJD02 | 240 | 200 | 150 | 650 | 420 | 112.5 | 225 | 12 | 9 |

| YJD04 | 260 | 230 | 180 | 758 | 526 | 140 | 280 | 15 | 11 |

| YJD06 | 300 | 250 | 200 | 778 | 536 | 150 | 300 | 15 | 11 |

| YJD08 | 320 | 270 | 220 | 798 | 546 | 160 | 320 | 18 | 11 |

| YJD10 | 340 | 290 | 240 | 880 | 628 | 170 | 340 | 18 | 13 |

| YJD12 | 360 | 310 | 260 | 900 | 638 | 180 | 360 | 18 | 13 |

| YJD14 | 380 | 330 | 280 | 920 | 648 | 190 | 380 | 20 | 17 |

| YJD16 | 400 | 350 | 300 | 960 | 678 | 200 | 400 | 22 | 17 |

| YJD18 | 420 | 370 | 320 | 980 | 688 | 220 | 440 | 22 | 17 |

| YJD20 | 450 | 390 | 340 | 1000 | 698 | 230 | 450 | 22 | 17 |

| Model | A | B | C | E | F | M | H | h | φ |

| 300*450 | 450 | 395 | 320 | 1120 | 690 | 225 | 450 | 20 | 12-Φ18 |

| 320*450 | 400 | 360 | 300 | 1090 | 680 | 230 | 450 | 20 | 12-Φ18 |

| 300*500 | 400 | 360 | 300 | 1090 | 680 | 300 | 500 | 20 | 12-Φ18 |

| 400*600 | 550 | 500 | 400 | 1300 | 960 | 300 | 600 | 20 | 12-Φ18 |

| 400*600 | 530 | 480 | 400 | 1400 | 1000 | 300 | 600 | 25 | 12-Φ18 |

| 500*680 | 630 | 585 | 500 | 1510 | 1100 | 340 | 680 | 25 | 12-Φ18 |

|

|

Feeding Small Granular Materials Impeller Feeders 16L/R 300mm Diameter Images |